Rotary Offset Press ZP-520/680/900/1200

1. High-speed rotary offset printing machine (with sleeve technology) owns more than 20 national and international patents.

2. Adopts continuous offset printing mode and variety printing sleeve technology, leading to fast printing speed and high printing quality.

3. The plate roller and the blanket roller adopts the air expansion sleeve, achieving short plate changing time and easy operation.

online service

2. Adopts continuous offset printing mode and variety printing sleeve technology, leading to fast printing speed and high printing quality.

3. The plate roller and the blanket roller adopts the air expansion sleeve, achieving short plate changing time and easy operation.

4. The inking system and water system are automatically adjusted according to printing sleeve. Optimized inking system makes inking move smoother, printing pressure more stable and easier to adjust.

5. Unwinder has automatic tension control and is equipped with web guider.

6. Printing tension controls automatically, the web passes smoothly even at high speed, stable printing tension ensures high-speed and high-precision printing.

7. This machine has the function of automatic pre-registration, automatic registration by photocell after set-up and second pass with registration.

8. Inline inspecting system can be installed according to user's requirement.

9. Based on offset printing units, machine can combine with other functions such as flexo, gravure, cold stamping, hot stamping, die cutting, embossing etc.

10. This machine is suitable for various substrates, such as: self-adhesive paper, paper and unsupported film (BOPP, PET, PP, PVC, etc.).

Main Technical Parameters:

Model

ZP - 480

ZP - 680

Max. Printing Speed

180m/min

180m/min

Printing Color

4 - 12(Colors)

4 - 12(Colors)

Max. Printing Width

460mm

660mm

Max. Web Width

480mm

680mm

Printing Repeat Length

380 - 690mm(15 - 27.5inch)

430 - 690mm(17 - 27.5inch)

Max. Unwinding Dia.

1000mm

1000mm

Max. Rewinding Dia.

1000mm

1000mm

Dimensions(L×W×H)

15.2M × 3.7M × 2.1M

Unwinder + Flexo unit with cold stamping + 5 Offset units + Flexo(varnishing) + Die - cutting unit + Rewinder

-

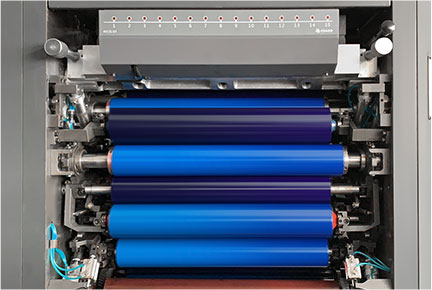

Heavy Offset Printing Unit

High quality heavy offset printing unit with well-designed inking system which can transfer ink fast & evenly, avoids gear mark and ghost image effectively.The printing quality can be highly improved.

-

Variable Printing Sleeve

When the printing job with different repeat length, just change both plate and blanket sleeve accordingly.The sleeve changing is very fast and efficient.

-

Automatic Ink Control System

One-button setting, ink control is automatically, because of ink supply automation and precision , it improves the printing efficiency & quality, and reduces wastage.

-

Matrix Unit

Snowball type waste collecting device, matrix speed synchronizes to the printing speed.

-

Human Machine Interface (HMI)

Touch control panel, faster operating speed.main control with 15inch large touch screen, friendly design and easy operation; each printing unit equips with 7inch touch screen, can be operated independently and easily. Error alarms will be displayed instantly, which shortens the trouble shooting and repairing time greatly

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Rotary Offset Press ZP-520/680/900/1200

1. High-speed rotary offset printing machine (with sleeve technology) owns more than 20 national and international patents.

2. Adopts continuous offset printing mode and variety printing sleeve technology, leading to fast printing speed and high printing quality.

3. The plate roller and the blanket roller adopts the air expansion sleeve, achieving short plate changing time and easy operation.

ZJR S350 Pro Hybrid (Flexo/Digital) Printing Machine

1. The whole machine adopts the latest servo control system and each printing unit is driven by independent servo motor, which ensure the accurate registration during high speed production.

2. The printing roller adopts sleeve type without gear which is light, easy, convenient and fast to change. This type of design is largely improve the printing quality and reduces the maintenance.

3. Motorised pressure adjustment system between anilox roller to plate and plate to substate makes the pressure setting very easy and fast, which greatly improve the efficiency.

WG S350 Digital Printing Machine

1. Print heads combination are flexible: multiple combination per requirements;

2. Max print speed up to 60m/min which is high efficiency and suitable for variable job application;

3. Max print width up to 350mm which expands application range and increases flexibility.

WG S350 UltraFlexible Printing Setup

1.Flexible print head combinations: Various combination choices to fit different requirements.

2.Max print speed up to 75m/min, balancing high efficiency and adaptation to various applications.

3.Max print width up to 310mm, expanding application range, better fulfilling different needs.